The metal and ceramic sintering process is used to compact a powder into a solid with the application of heat. The samples are heated in a sintering furnace to a temperature lower than the melting point which causes the powder particles to bond together into a compact mass.

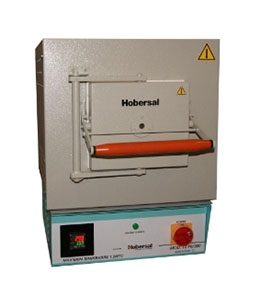

Hobersal offers a very complete range of furnaces for sintering, vacuum furnaces, controlled atmosphere furnaces, muffle furnaces, ovens and high temperature muffle and tube furnaces

Metal and ceramic sintering are processes used to create solid, high-strength objects by heating and compacting powdered metal or ceramic materials until they fuse together. Sintering is a key process in the production of a wide variety of metal and ceramic products, from simple components to complex parts with intricate shapes and structures.

In metal sintering, metal powder is placed in a mold or die and heated to a temperature below its melting point, but high enough to cause the particles to fuse together. This process creates a strong, porous structure that can be further processed, such as through machining or coating, to create a final product. Metal sintering is used to produce parts for a range of applications, including automotive and aerospace components, medical devices, and industrial machinery.

In ceramic sintering, similar processes are used to create solid ceramic objects. The ceramic powder is compacted into the desired shape and then heated to a temperature high enough to cause the particles to bond together. This process is often used to produce ceramic components with high strength and heat resistance, such as cutting tools, electrical components, and high-temperature insulation.

Sintering can be done using different methods, such as hot pressing, spark plasma sintering, and microwave sintering, depending on the materials being used and the desired properties of the final product. Sintering is an important process in the field of materials science and engineering, and its applications are widespread in industry and research

Hobersal sintering furnaces offer the best results, quality and performance in sintered parts