Standards: Ceramic and metal sintering process under vacuum or controlled atmosphere

Sintering vacuum furnaces for your 3D metal and ceramic printing applications.

Vacuum and controlled atmosphere muffle furnaces to get the best results for vacuum soldering and brazing, vacuum annealing, sintering etc. In general, a vacuum furnace is required for any type of heat treatment in a defined, mostly non-oxidising, atmosphere.

The metal and ceramic sintering process is used to compact a powder into a solid with the application of heat. The samples are heated in a sintering furnace to a temperature lower than the melting point which causes the powder particles to bond together into a compact mass.

Hobersal offers a very complete range of furnaces for sintering, vacuum furnaces, controlled atmosphere furnaces, muffle furnaces, ovens and high temperature muffle and tube furnace

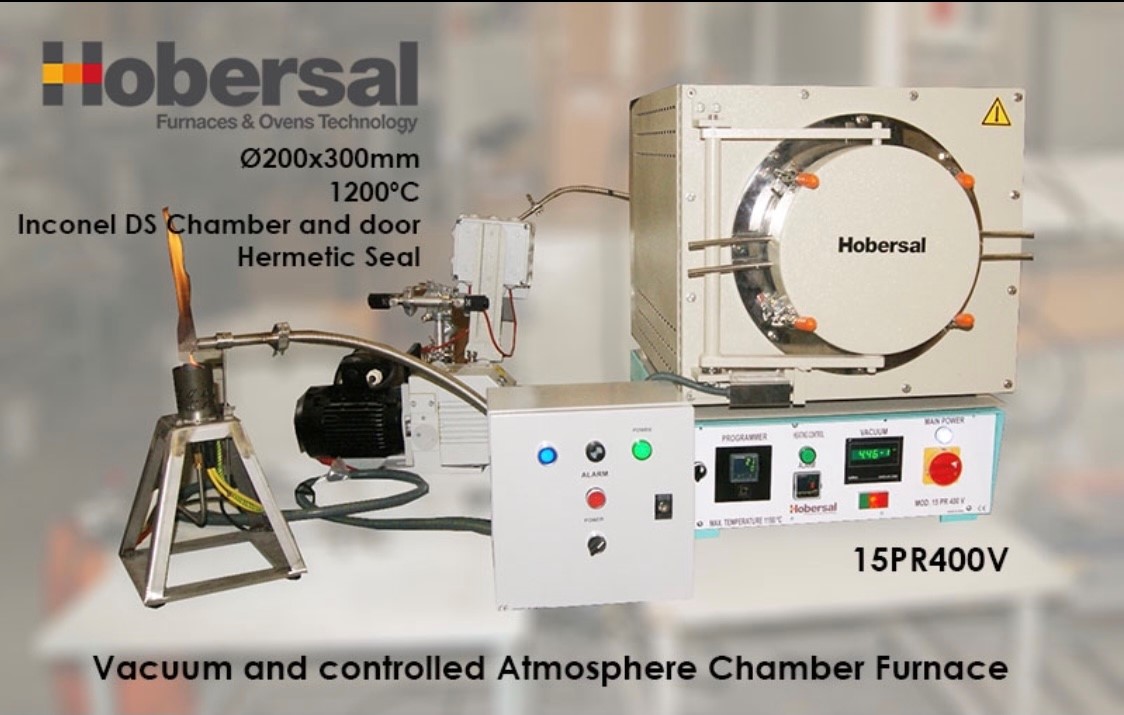

Vacuum chamber / muffle furnace Hobersal PR-V series

Vacuum, inert and combustion atmospheres

HOBERSAL Furnaces For Metal and Ceramic 3d Printing Processes and Additive Manufacturing

Ceramic and metal Sintering, Annealing, debinding, fusing, curing

Works under vacuum and controlled atmosphere to ensure the sintered part is not contaminated by oxygen

3D Additive manufacturing

- Metals sintering: Debinding, sintering, stress-relieving, solution annealing and hardening

- Ceramics, Glass, Composites, Sand sintering: Debinding, sintering, drying and curing

- Plastics sintering: Curing, tempering, drying

- Temperatures 1.150 ºC

- Inner volume:

– Ø 200 x 300 prof.

– Ø 300 x 400 prof.

– Ø 350 x 400 prof.

– Ø 400 x 500 prof.

– Ø 500 x 500 prof.

– Custom designs

EV-7 Automatic Programmable & Controlled Atmosphere/Vacuum System

CHARACTERISTICS:

- Electronic-valve equipment to control gas atmosphere or/and vacuum.

- Eurotherm programmable controller equipment (10 programs/25 segments) with alarm (Over-heating Protection)

- Eurotherm programmable controller EPC Series and data logger software

This system enables complete automatic electronic programming and controlling of the furnace chamber’s atmosphere, with automatic gas introduction, replacement and/or extraction.

Technical Details

- Pantograph side door

- Incoloy chamber and door

- Hermetic seal refrigerated by water

- Let work 24/7 in continuous mode

- 4 heating plates with Kanthal AF

- Low thermal mass insulation

- Built with low density ceramic bricks and ceramic fiber

- Double isolation chamber

- Outside casing in metal sheet painted ( inox as optional)

- Incoloy tray included

- Thermocouple type K

- Compact and lightweight furnace

- Easy to replace all the spare parts by the end user

- Furnace control:

- Under / Side the furnace

- Solid state relay

- PAD Digital control. Microprocessor. Alarm.

- Furnace disconnection by thermocouple break

- Manufactured under the CE

- Accessories

- Vacuum pump 10 ̄ ² and 10 ̄ ³

- O2 Sensor + controller (ppm)

- Water cooling equipment

- Security class II. Over-temperature protection

- Hydrogen burner

- Flow meter box (Gas supply system)

- Optional regulation

- Ramp programmer up to 64 steps

- Eurotherm EPC 3004 Series + Data logger Itools sofware by Ethernet (Optional)

- Eurotherm Nanodac Series +Data logger and Itools sofware by Ethernet according AMS2750E and 21CFR Part 11 (Optional)

What is a vacuum furnace?

Hobersal vacuum furnaces are furnaces for vacuum heat treatment.

The absence of air inside the chamber avoids oxidation during the process and guarantees the best results.

Which applications are most used in a vacuum furnace?

Vacuum furnaces are used in a wide range of applications in both production industries and research laboratories.

Vacuum furnaces are used to carry out processes such annealing, ceramic and metal sintering, brazing and heat treatment consistency and low contamination in a defined, mostly non-oxidising, atmosphere.

Types of atmospheres possible in a vacuum furnace

Vacuum is already an atmosphere and can be 1Mbar, x10-2Mbar and x10-5Mbar. Additionally, as a vacuum furnace allows complete removal of the air atmosphere, it is also possible to work with various gases or mixtures, such as Nitrogen, Argon, Helium, Formigas, Hydrogen, Carbon Monoxide…

Why should we choose Hobersal vacuum furnaces?

In addition to a vacuum furnace, Hobersal vacuum furnaces allow to work in controlled atmosphere and vacuum in the same process / program, how?

Hobersal vacuum furnaces with the EV-7 system allow to work in vacuum and controlled atmospheres in the same process.

A set of vacuum solenoid valves and a program designed with Eurotherm allows us to activate / stop vacuum, introduce / stop gases and aeration of the chamber.

It also allows vacuum at high temperatures thanks to our chamber design.

What types of vacuum furnaces can we work with Hobersal?

· Tube furnaces Hobersal ST and HTF series with vacuum flanges up to 1150ºC – 1300ºC -1600ºC -1650ºC -1800ºC and 1900ºC

· Vacuum muffle furnaces Hobersal PR-V series up to 1150ºC

· Bottom loading furnaces Hobersal HOB33 with Gas-tight Alumina retort (Inverted crucible)

#vacuumfurnace #vacuum #sintering #annealing #brazing #vacuumheattreatment #hobersal #heating