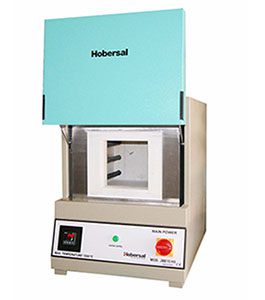

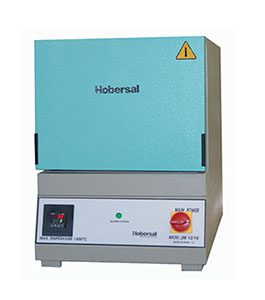

Muffle Furnace (Metal and Ceramic Sintering Chamber furnaces)

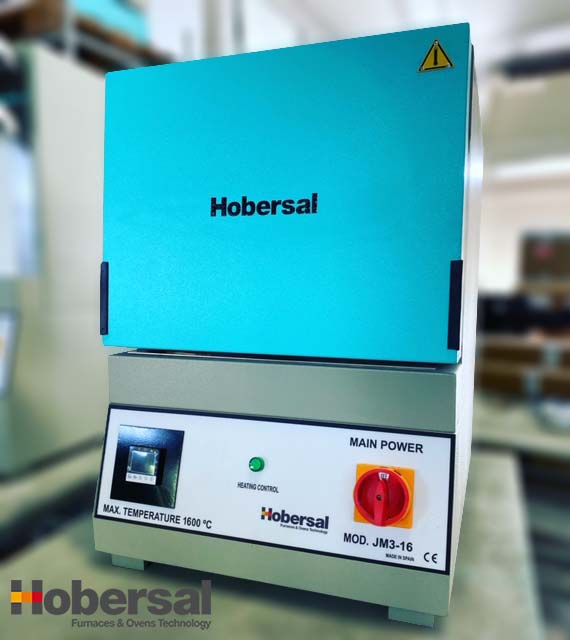

High temperature muffle furnace JM series (SiC)

- Temperatures up to 1.600 ºC

- Vertical lift door

- Let work 24/7 in continuous mode

- SiC High quality Silicon Carbide heating elements Kanthal

- Ramp programmer up to 64 steps

- Fast heat

- Inox chamber.

- Low thermal mass insulation

- Built with low density and ceramic fiber

- Double isolation chamber + air chamber

- Outside casing in metal sheet painted ( inox as optional)

- Ventilated via rear by ceramic chimney

- Thermocouple type S

- Compact and lightweight furnace

- Easy to replace all the spare parts by the end user

- Furnace control:

- Under the furnace

- Solid state relay

- PAD Digital control. Microprocessor. Alarm.

- Safety Shut-off

- Thermocouple break shut-off

- Turns off upon door opening

- Manufactured under the CE

- Accessories

- Ceramic tray

- Smoke chimney

- Forced smoke chimney

- Security class II. Over-temperature protection (OTP)

- Inlet gas entry

- Flow meter box

- Optional regulation

- 1 program 8 steps (Programmer)

- 4 program 15 steps (Programmer)

- Eurotherm EPC series (Ramp Programmer + software Itools) 10 Progs / 25 steps – via Ethernet (Curves downloadable in CSV-Excel)

Standards: Ceramic and metal sintering process

Sintering furnaces for your 3D metal and ceramic printing applications.

Technical ceramics, sintering, debinding, bioceramics process

.

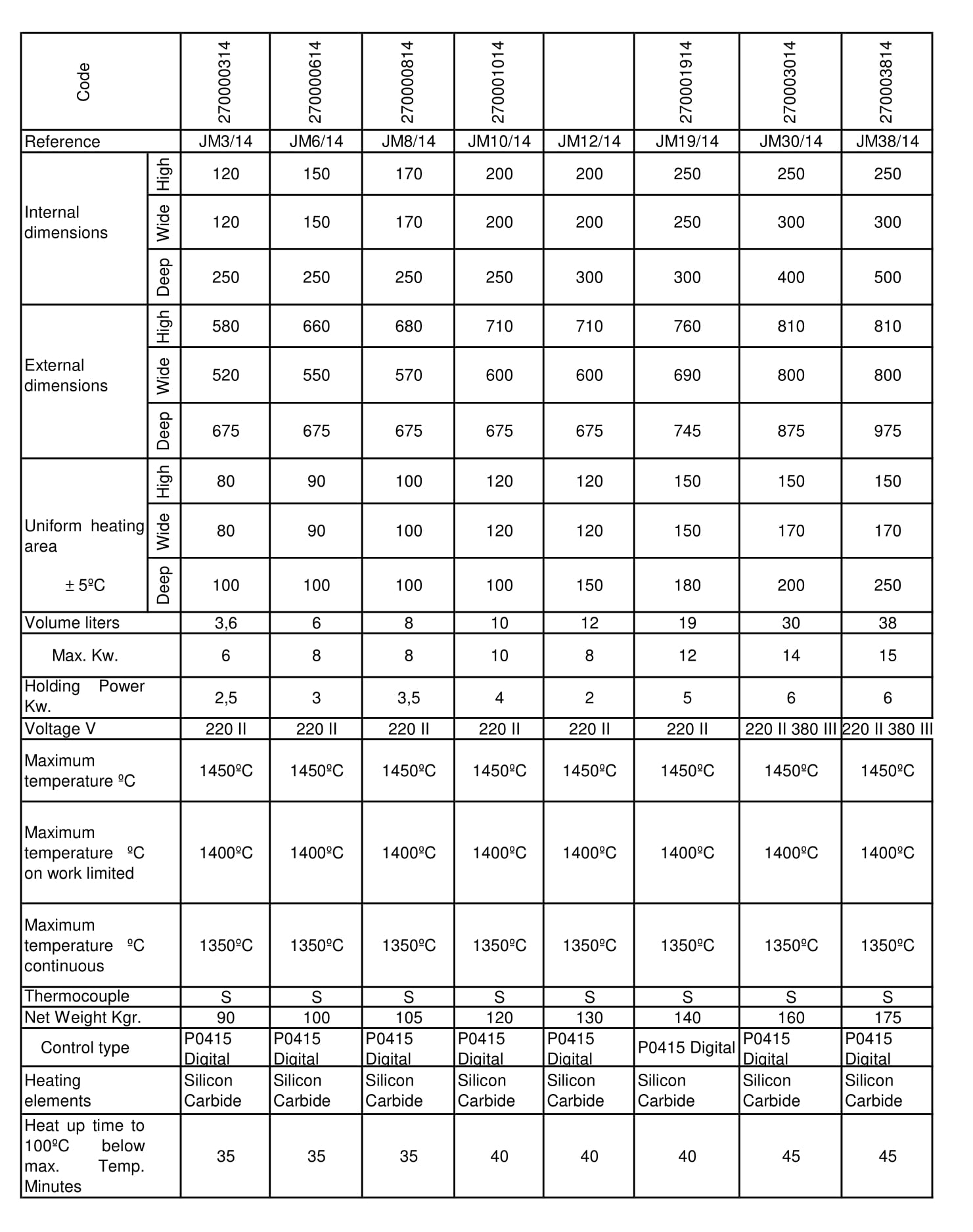

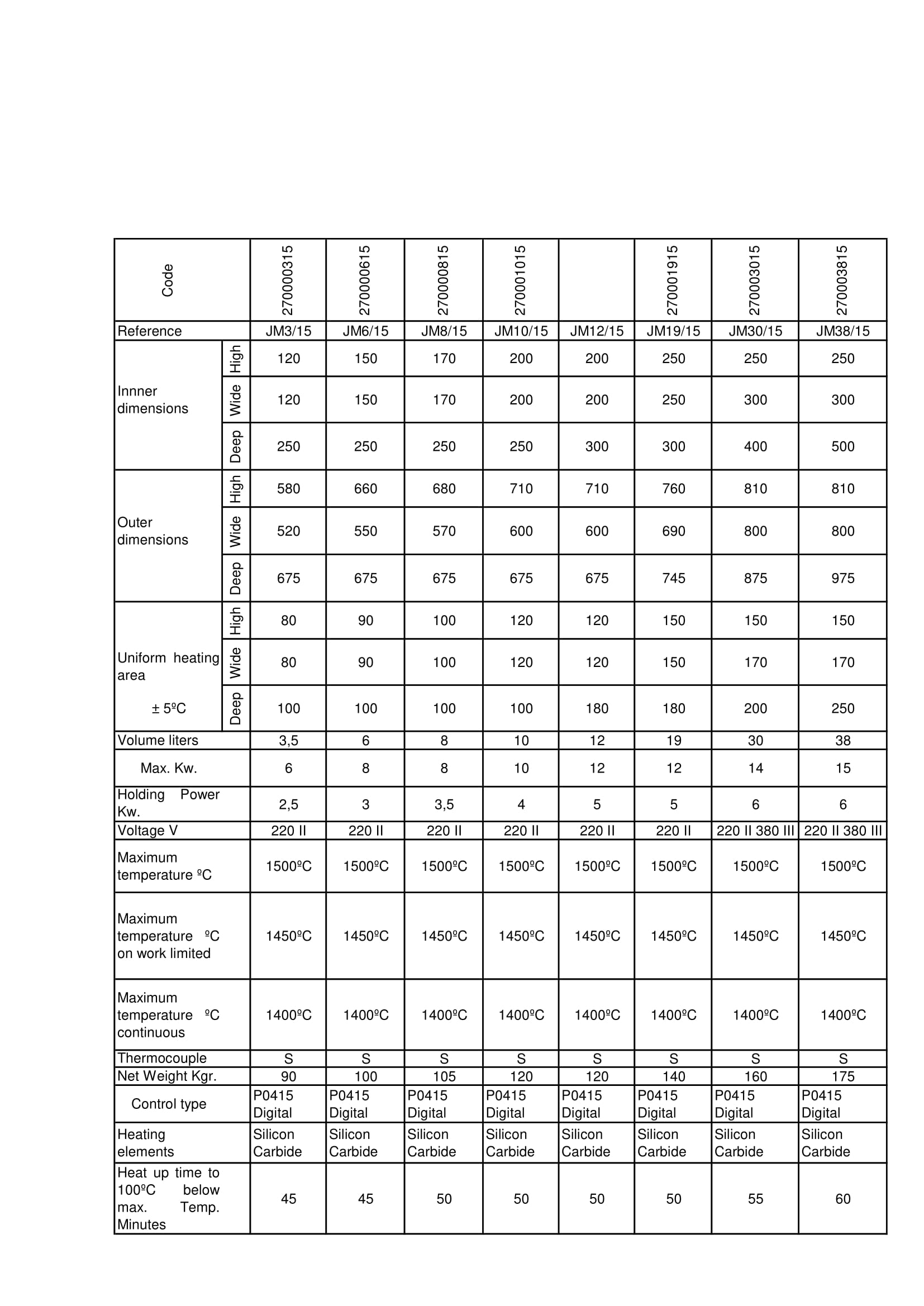

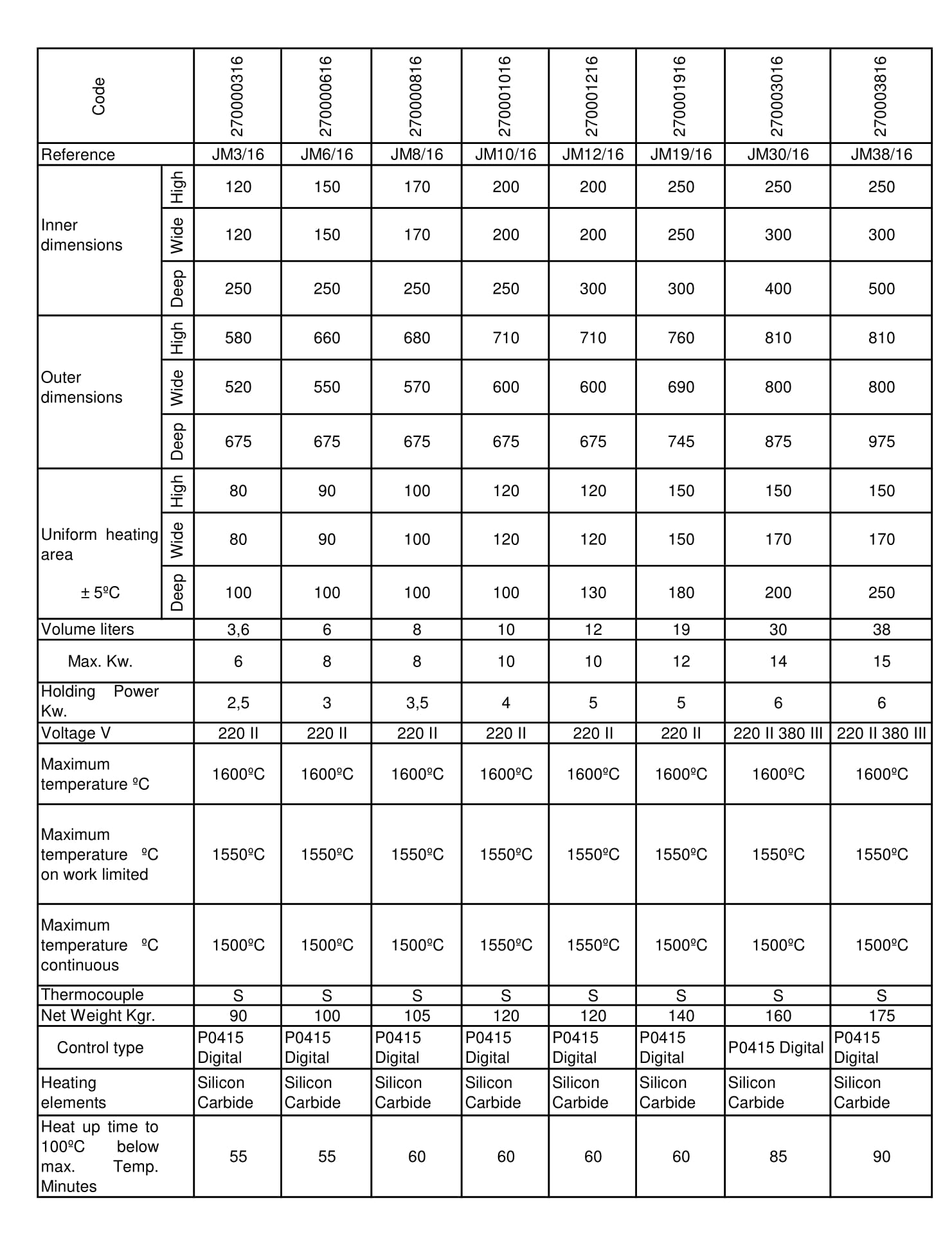

Technical details

JM Series up to 1400ºC – 1500ºC – 1600ºC (3 pages)