Muffle Furnace

For ceramist, pottery and industry

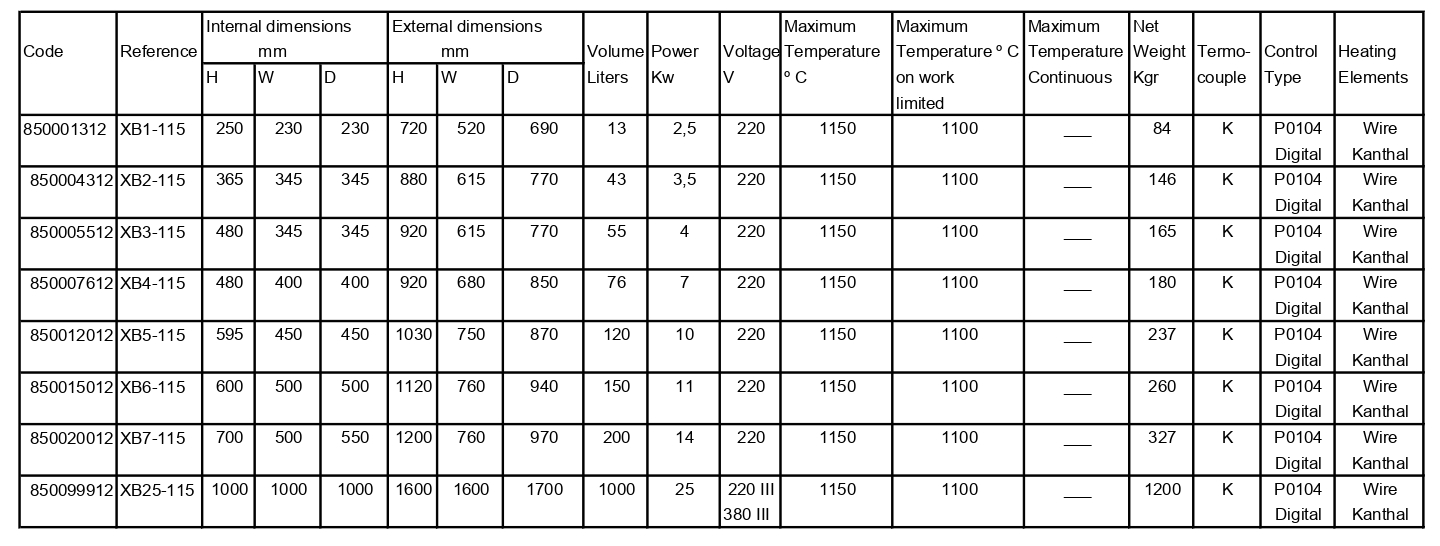

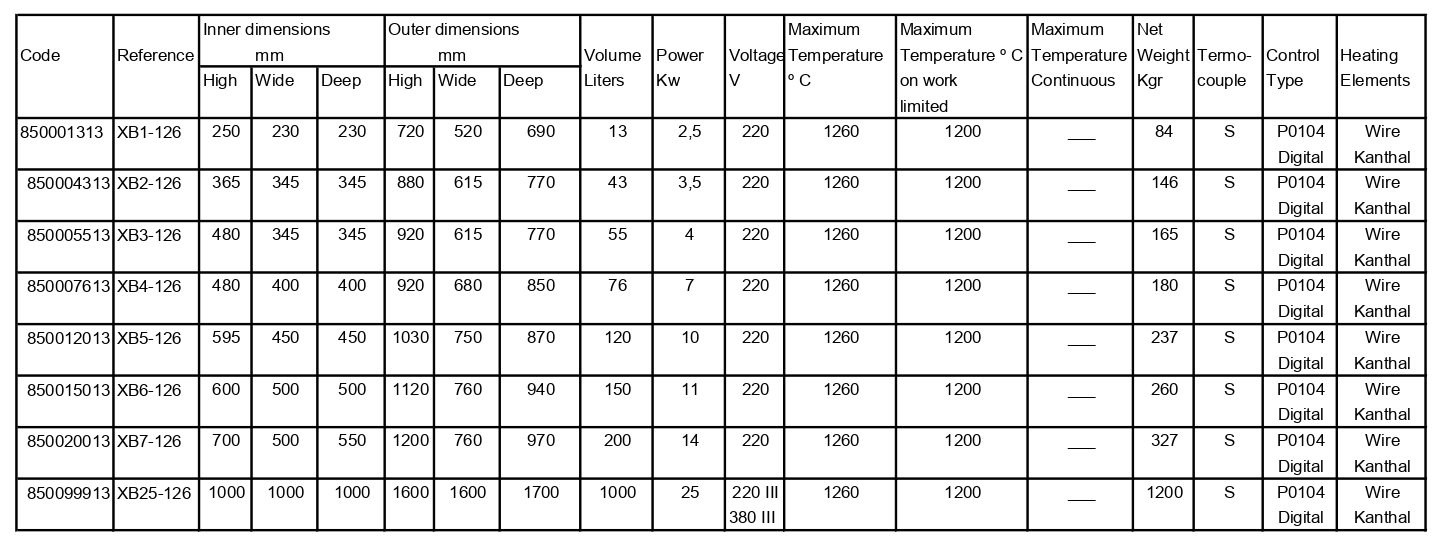

Economy chamber furnaces model XB series

- Temperature 1.150 ºC – 1.260ºC and 1400ºC

- Side door

- From 13 litros to 2.000 litres

- 2 heating zones with Kanthal AF

- 1 program 8 steps ( Ramp programmer)

- Low thermal mass insulation

- Built with low density ceramic bricks and ceramic fiber

- Double isolation chamber

- Outside casing in metal sheet painted ( inox. Optional)

- Ventilated via rear by ceramic chimney

- Thermocouple type K or S

- Compact and lightweight furnace

- Furnace control:

- Under the furnace or side

- Solid state relay

- PAD regulation. Digital control. Microprocessor. Alarm.

- Furnace disconnection by thermocouple break

- Manufactured under the CE

- Accessories

- Ceramic tray

- Refractory steel tray

- Smoke chimney

- Forced smoke chimney

- Security class II. Over-temperature protection

- Inlet gas entry

- Flow meter box

- Optional regulation

- 4 program 15 steps (Programmer)

- Eurotherm data logger and programmer communication by Ethernet

Technical details

the XB range of muffle furnaces are economical furnaces suitable for the heat treatment of small to large pieces and for artistic and industrial ceramics.

Furnaces made of ceramic brick and with the heating elements embedded in the two sides of the furnace for temperatures of 1150°C and 1260°C.

Heating elements on support tubes radiating freely into the furnace chamber provide for particularly short heating times and a maximum temperature of 1400 °C

Furnace control located on the side of the furnace to avoid problems with loading and unloading of parts

.